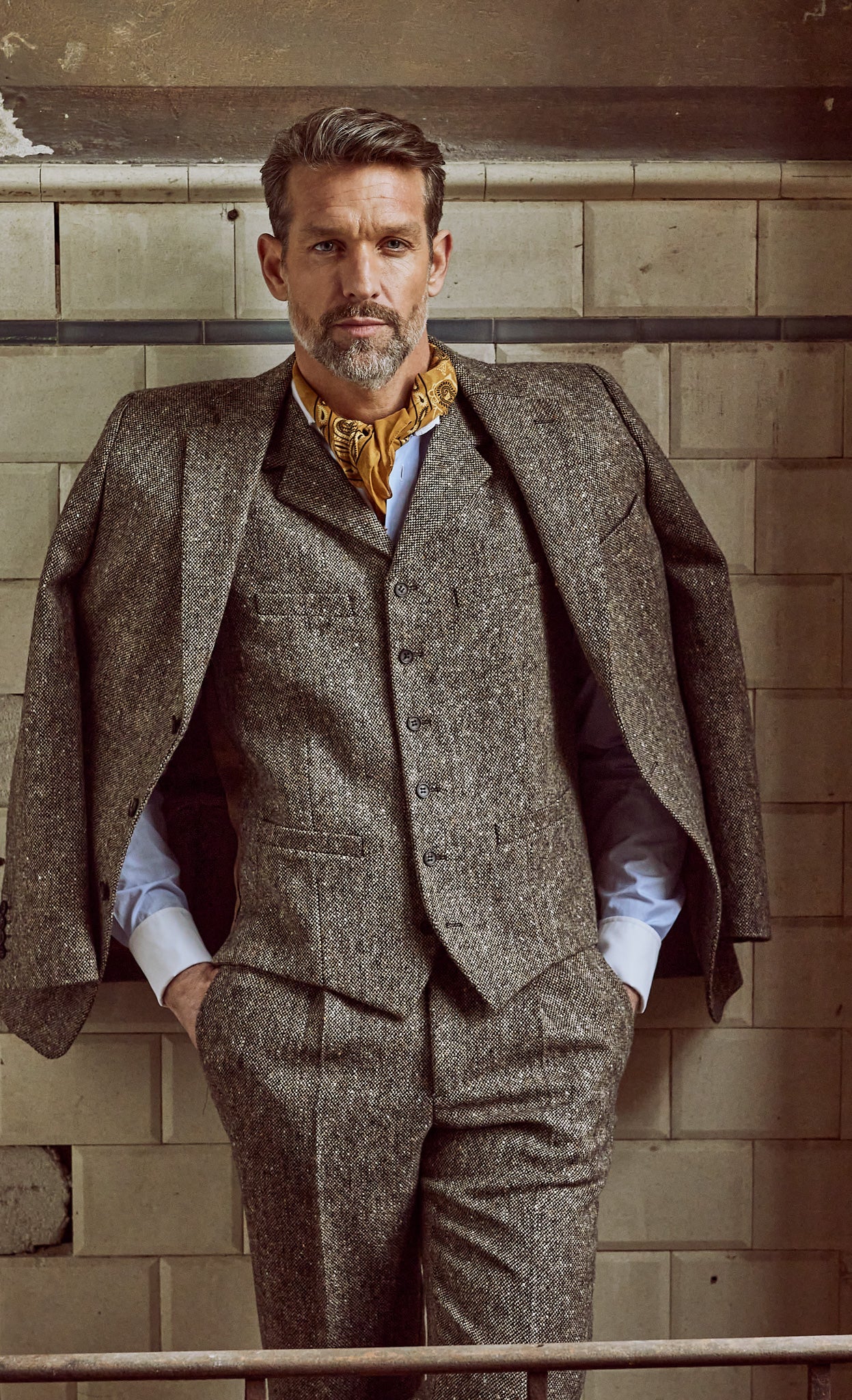

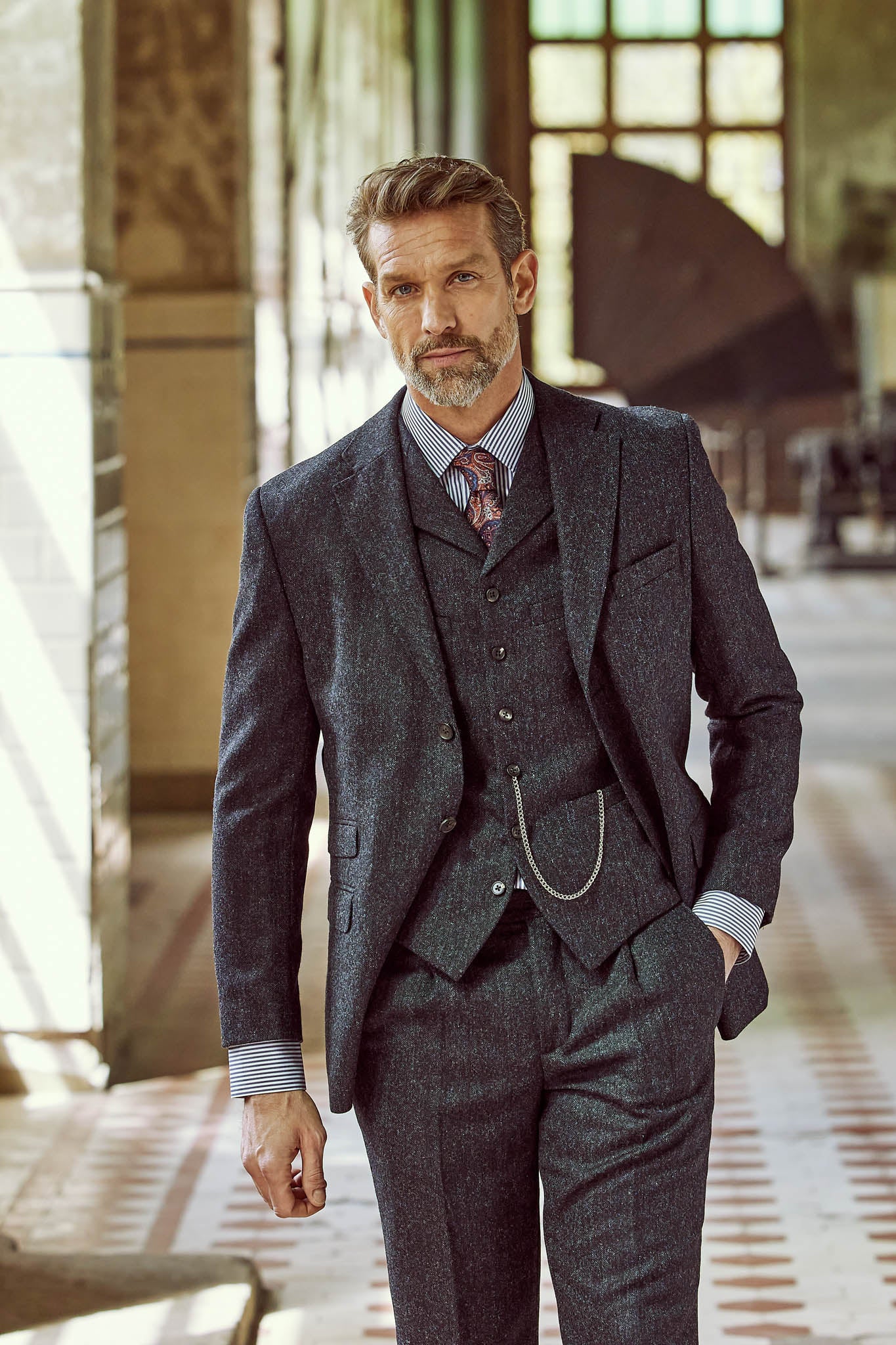

What is tweed?

Tweed is a fabric made from pure new wool and produced in the north of Scotland. The word probably derives from its typical structure, called twill, or tweel in Scotland. What is more commonly known in Germany as "twill weave" or "Zwillich" refers to the weave/woven weave that creates a diagonal pattern in the fabric.

Originally, tweed was primarily used to describe fabrics handwoven from hand-spun yarns. Thus, it was mostly coarse wool yarn, but also warp and worsted yarns, which formed the basis for the small weave patterns.

A note that is important to us: Our producers support animal welfare and therefore we only carry "mulesing-free wool"!

The history of tweed

The origins of tweed most likely lie in the rural regions of Scotland and Ireland. Tweed was characterized by its particularly robust construction, protecting men working outdoors from the cold and rainy British climate. Since sheep also adapt to the harsh climate, the wool of Scottish sheep is particularly well suited for tweed. Their wool is correspondingly thick, robust, and waterproof.

The history of tweed

Dyeing was always done with natural dyes: orange was obtained from ragwort, wheat and iris provided the green, and lichen the red. But soon, tweed was no longer just the fabric of farmers. After the English royal family acquired Balmoral Castle, the purchase of a country estate in Scotland became established throughout English society. To distinguish themselves from the rest, large landowners designed their own tweed patterns, known as estate tweed, which was worn exclusively by their servants. In keeping with the Scottish tradition of dressing according to clan affiliation.

How is tweed made?

The production process begins with the dyeing of the wool. Large batches of wool are first placed in a closed vat. There, the spinning process takes place to extract all the moisture from the fibers. Only then does the wool receive its final color. To achieve the typical tweed pattern, the individual dyed batches are shredded and then blended.

The individual wool fibers are then pulled by machines in the same direction and passed through a series of rollers to stretch the fibers. The correct amount of fiber is pulled through another machine to create a very loosely organized thread. To give the yarn the strength required for weaving, it must now be spun into a strong thread. For this, it is twisted six to eight times, which gives the yarn much greater tensile strength.

Film on the history of tweed

Our Tweed Manufactories

Lovat Tweed

Lovat Tweed is always warm and very durable, even in wet conditions. Its color variations are reminiscent of the Scottish landscape.

Lovat Tweed Manufactory

Harris tweed

Harris Tweed is particularly durable, shines in unique colors and can be easily combined with other fabrics.

Harris Tweed Manufactory

Moon Tweed

Moon Tweed's luxurious feel creates a special feel-good factor and keeps you warm even in cool temperatures.

Moon Tweed Manufactory

Magee Tweed

Magee Tweed impresses with its particularly long durability and heavy fabrics from the traditional County Donegal in Ireland.

Magee Tweed Manufactory

John Hanley Tweed

John Hanly works exclusively with natural fibers and places great emphasis on sustainable and ethical production.

John Hanly Tweed Manufactory

Marling & Evans Tweed

Marling & Evans rightly emphasizes the distinctive, unmistakable character of its tweed fabrics. The spinning, weaving, and finishing mills are located in Huddersfield, England.

Marling & Evans Tweed Manufactory